The 66 has had a great summer cruising the fabulous Greek islands and the Turkish coast. She is proving to be a real pleasure to sail and it all seems so effortless and calm. She has dealt with all sorts of weather this summer from 40 + knots of the Meltimi to flat calms, to the hottest August days to Indian style monsoon rains and come through it all with flying colors.

Shes now back in the Bodrum area and will probably again spend the winter ashore. . We had a few little niggles with some Whale and Lewmar equipment but both companies were fast and responsive in getting replacements out to the boat with great efficiently all under warranty – great service !

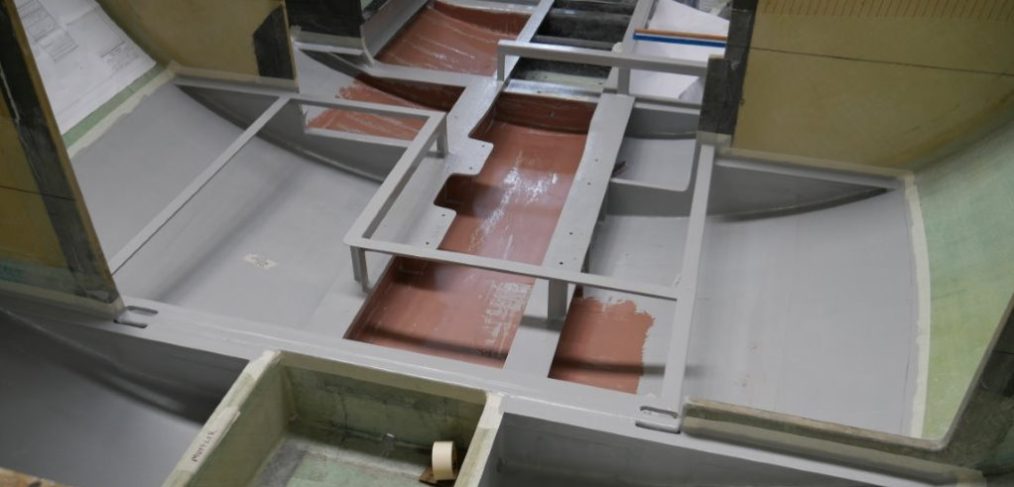

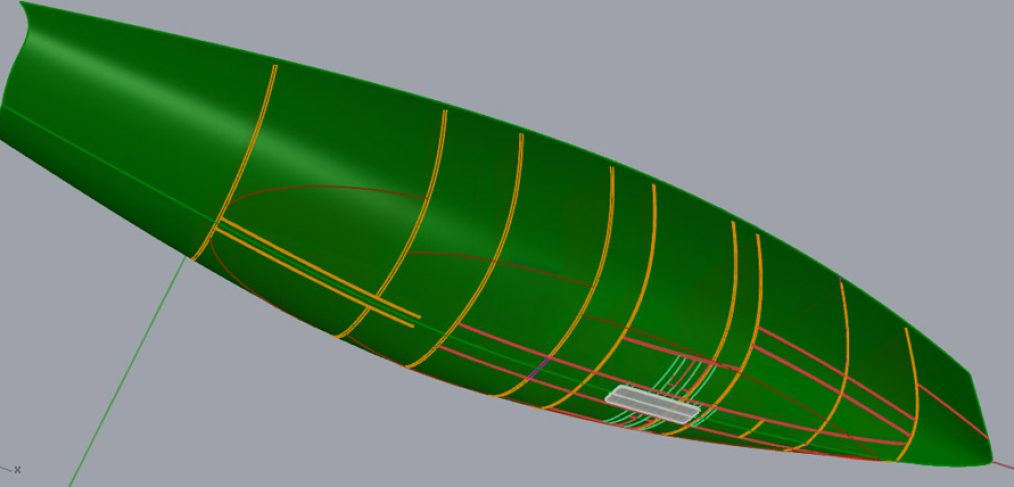

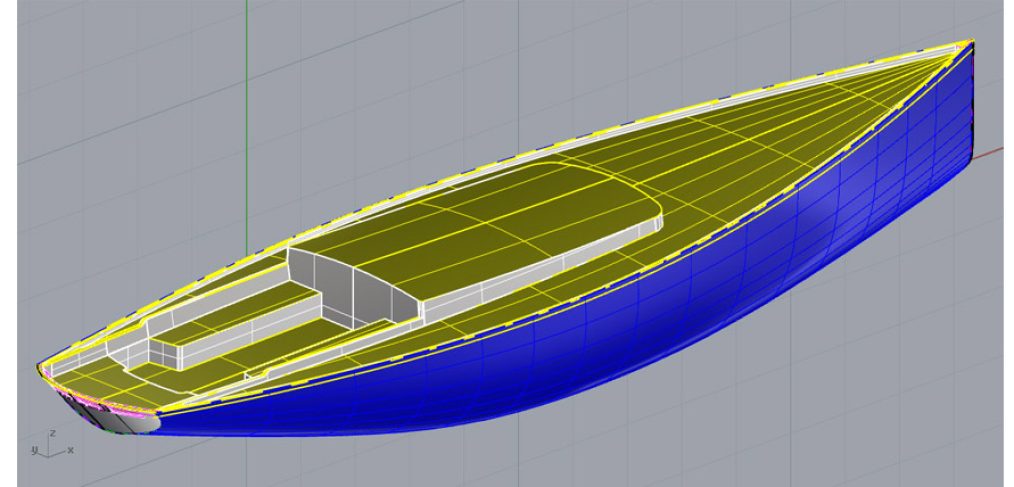

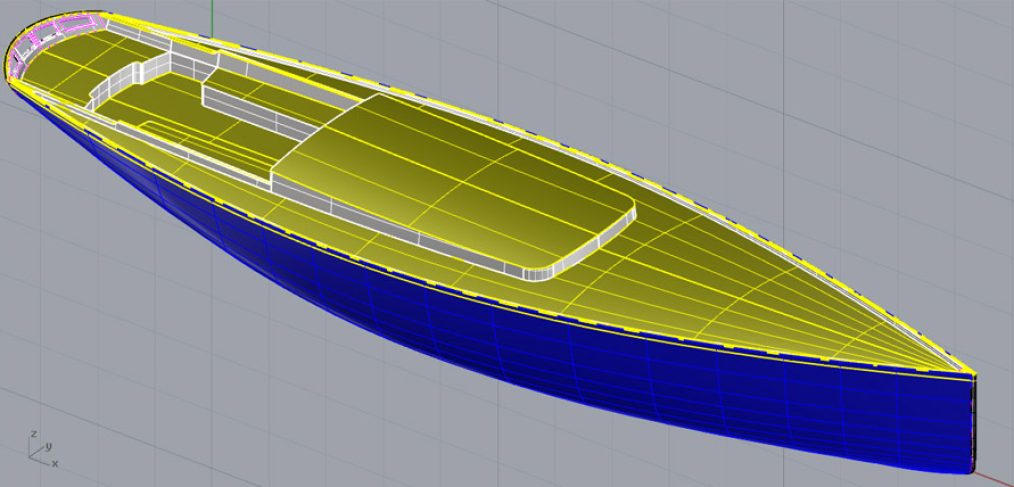

It has been a busy few months at the yard in terms of finishing off the structure of the hull, grid system and bulkheads and the start of the deck. As one can see from the photos there is a lot of carbon in the grid system and supports, about 250kg’s in the grid system and re-inforcements on the bulkheads and supported areas which will mean an extremely stiff yacht ! A lot of time has been spent 3 d modeling the final systems drawings for maximum usage of the areas for tanks and equipment to make sure that all areas are accessible for easy servicing of equipment in the long term, we would be pleased to explain this in further detail. We have also had some renders commissioned which I am sure you will agree show the fabulous lines of the yacht and how she will finally look, an exciting prospect !!

June has been a month where the focus has been on the interior skin lamination and the start of the interior structure. The yard are looking to complete the interior structure and have the bulkheads in position by the end of July and then the preliminary installation work will commence. Most of the equipment including the rig, deck gear, steering system and engine have all been ordered during the month.

“MAZU”, the first of the PC66’s has spent the winter ashore near Bodrum under a full winter cover where a remarkably short list of warranty items were attended to by Metur and preparations are now focused on getting her ready for re-launch. A few pictures of her launch from last year.

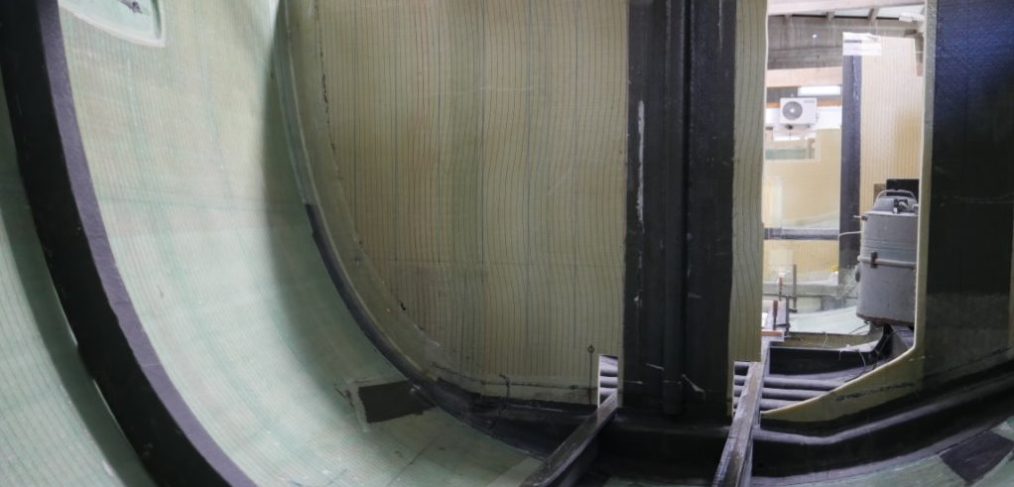

A busy month at the yard which has seen the Coracell M foam outer skin laminated with e-glass, vacuumed and then epoxy filled and partially faired, infact below the water line fairing is completed. The slightly scary process of turning the hull with the jig inside was completed and she is now sitting in her build cradle with the jig removed. We call already see her beautiful lines. The next month will be all about forming the internal structure, its very much a carbon based grid system engineered by Hoek Design to be light and very strong. The bow of the boat looks slightly strange at the moment as the boat has a false bow which is a safety feature used on high end race boats where if one was unlucky enough to hit an object at speed, the false bow is designed to break off whilst maintaining the integrity of the hull. As a further safety measure there is also a watertight bulkhead immediately behind the bow as well as in the aft section.

The foam structure for the hull has been competed and lamination has started. You can see the cove line, hull windows and keel recess have all been prepared. The foam is specified in different densities depending on the load areas as specified by the designers. Its been a busy month ordering a lot of the equipment such as the engine, drive train, steering as well as much of the deck gear. Lamination should be completed by the end of the month and then probably in mid May the hull will be turned and the internal structure will be added.

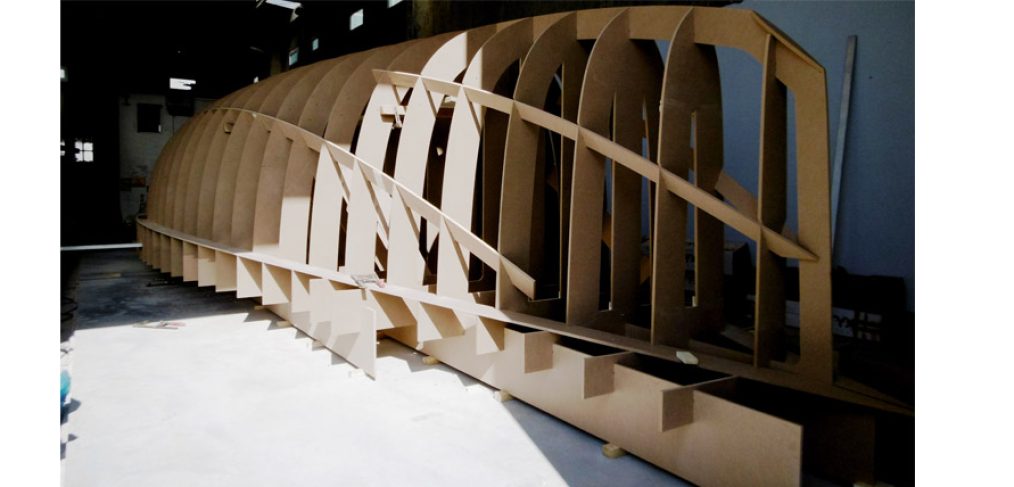

The build started in the second half of Febuary with the jig arriving and being set up the week earlier. Exciting times for all. There are also some 3 d images showing the hull ines and also the preliminary internal structure. The photos of the jig in place are starting to give us a glimpse of the stunning hull shape. The Gurit M foam will then be laid over the jig in long strips and then glued together with epoxy. Once this is completed then the laminate will be laid and epoxied and then vacuumed to the hull.